Asphalt powder

Product Introduction

The function of asphalt powder: [Packaging] Ton bags, woven bags, and mother bag packaging.

Raw material preparation and characteristics:

High-temperature asphalt is a type of coal tar asphalt with a high softening point and good thermal stability, which is widely used in the manufacture of high-quality carbon materials. High-temperature asphalt powder is a small particle of high-temperature asphalt, with a particle size usually between 0.1 and 1.0 millimeters. This powder has good fluidity and compressibility and can be used to prepare carbon materials with dense structures

Product Usage

The application of high-temperature asphalt powder in the field of refractory materials is particularly noteworthy. As an important component of high-temperature equipment, the performance of refractory materials directly affects the operational efficiency and safety of the equipment. High-temperature asphalt powder plays an indispensable role in the production of refractory materials due to its good adhesion, plasticity, corrosion resistance, and improved thermal conductivity.

Firstly, high-temperature asphalt powder has good bonding performance, which can firmly bond the aggregates in refractory materials together, forming a dense refractory structure. This not only improves the overall strength and stability of refractory materials but also effectively prevents material peeling and cracking at high temperatures.

Secondly, high-temperature asphalt powder acts as a plasticizer in refractory materials. It gives the material a certain degree of flexibility and plasticity at high temperatures, thereby improving the thermal shock stability of refractory materials. This is of great significance in reducing cracking and peeling caused by temperature changes.

In addition, components such as polycyclic aromatic hydrocarbons and quinoline compounds in high-temperature asphalt powder have antioxidant and anti-corrosion effects. They can slow down the oxidation reaction of refractory materials in high-temperature environments and extend the service life of refractory materials. This is crucial for ensuring the long-term stable operation of high-temperature equipment.

Finally, the addition of high-temperature asphalt powder can also improve the thermal conductivity of refractory materials. This means that refractory materials can better dissipate heat and improve heat dissipation performance. This is of great significance for the efficient operation of high-temperature equipment such as steelmaking furnaces and glass kilns, which helps to reduce energy consumption and improve production efficiency.

In summary, high-temperature asphalt powder, as a material with extensive application value, its source, use, and important role in the field of refractory materials cannot be ignored. With the advancement of technology and the improvement of processes, it is believed that high-temperature asphalt powder will have broader application prospects and deeper research and development space in the future. At the same time, we should also pay attention to environmental protection issues in its production process, ensuring that sustainable development can be achieved while promoting economic development.

Production Process

Coal tar pitch powder is generally processed from high-temperature coal tar pitch with a softening point above 105 ℃.

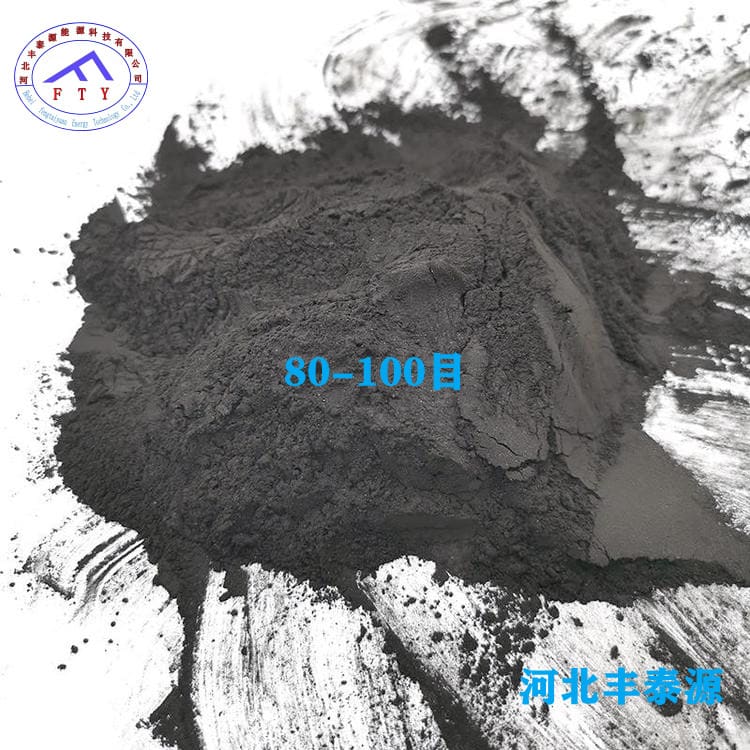

Asphalt powder is a method of crushing high-temperature asphalt using a crusher or Raymond mill, resulting in the solid asphalt presenting as particles or fine powder at room temperature. It has a wide range of uses. Various indicators can be customized, with particle sizes of 0-3mm, 0-6mm, 80-100 mesh, 100-200 mesh, and stable quality. Mainly used for activated carbon, refractory materials, anhydrous gun mud, ramming materials, graphite products, carbon products, electric carbon products, waterproof materials, waterproof rolls, asphalt paint, oilfield additives, petroleum drilling, recycled rubber, etc.

Product features: Asphalt powder

【 Packaging 】 Packaging in ton bags, woven bags, and mother and child bags.

Packaging and storage:

Packaging is 25Kg/bag

Packaging in ton bags, woven bags, and mother and child bags.

This product is easy to absorb moisture and is made of moisture-proof plastic inside. It is stored in a ventilated, cool, and dry place to prevent moisture and rain.

Product Features and Applications

Used in carbon factories, carbon binders, graphite fabrics, refractory material binders, activated carbon, gun mud, coke, etc. Our factory has professional equipment that can customize the coarse and fine mesh size of asphalt powder according to customer needs. It can produce 0-3mm, 0-6mm, 80-100 mesh, 100-200 mesh, and can produce 300 tons per day.