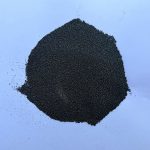

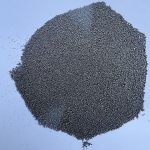

Ball pitch

Product Features and Uses

Spherical asphalt generally softens above 115 ° C, as the name suggests. Spherical asphalt has the appearance of a small grain-like sphere with a uniform particle size of 0-2mm. The sieving rate is 80%, and it has the characteristics of fixed carbon, toluene insoluble substances, high resin content, and low ash content. Widely used as an additive in blast furnace mud, blast furnace iron hook material, blast furnace spray repair material, ramming material, and casting material, as well as amorphous refractory materials and carbon materials, it can play a role in bonding and carbonization, and improve the high-temperature resistance and erosion resistance of products.

Preparation Process

Spherical asphalt is made by heating, dissolving, spraying, and cooling coal tar asphalt. Add the raw asphalt used in the experiment to the asphalt dissolution kettle and heat it for dissolution. At the same time, turn on the power supply of the electric heating coil, and the liquid asphalt will be sprayed out from the nozzle, and atomized into small particles by air. Asphalt particles are naturally cooled into semi-finished products by air inside the cooling tower, and then fed into a three-dimensional vibration screening filter at the bottom of the cooling tower for classification, resulting in spherical asphalt products that meet the requirements

This product has the characteristics of fixed carbon, insoluble toluene, high resin content, and low ash content. It is widely used in blast furnace iron hook materials, blast furnace spray repair materials, ramming and casting materials, as well as amorphous refractory materials. It is an additive to carbon materials and can play a role in bonding and carbonization, improving the product's ability to withstand high temperatures and erosion